Product Details

Brand Name: Tunisng

Certification: SGS , ISO9001

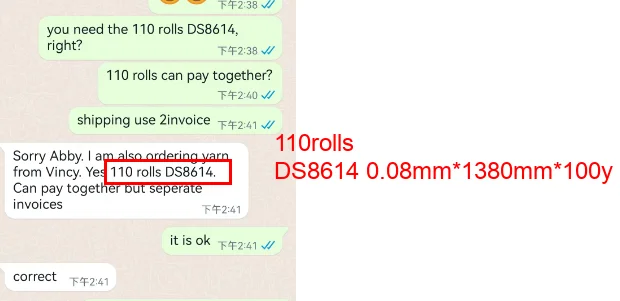

Model Number: DS8614

Payment & Shipping Terms

Minimum Order Quantity: 100Y

Price: negotiable

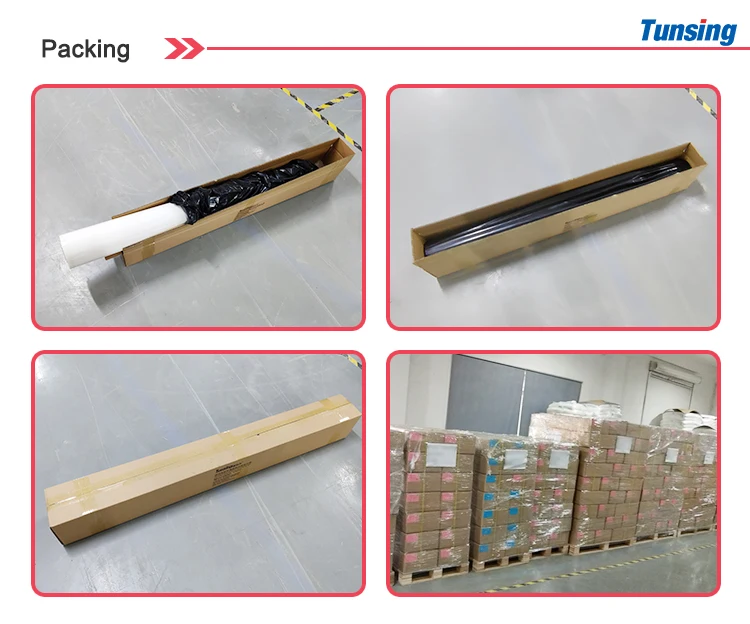

Packaging Details: 1 roll per ctn

Delivery Time: 5-7days

Payment Terms: T/T, Western Union, L/C, Paypal

Supply Ability: 50000m

|

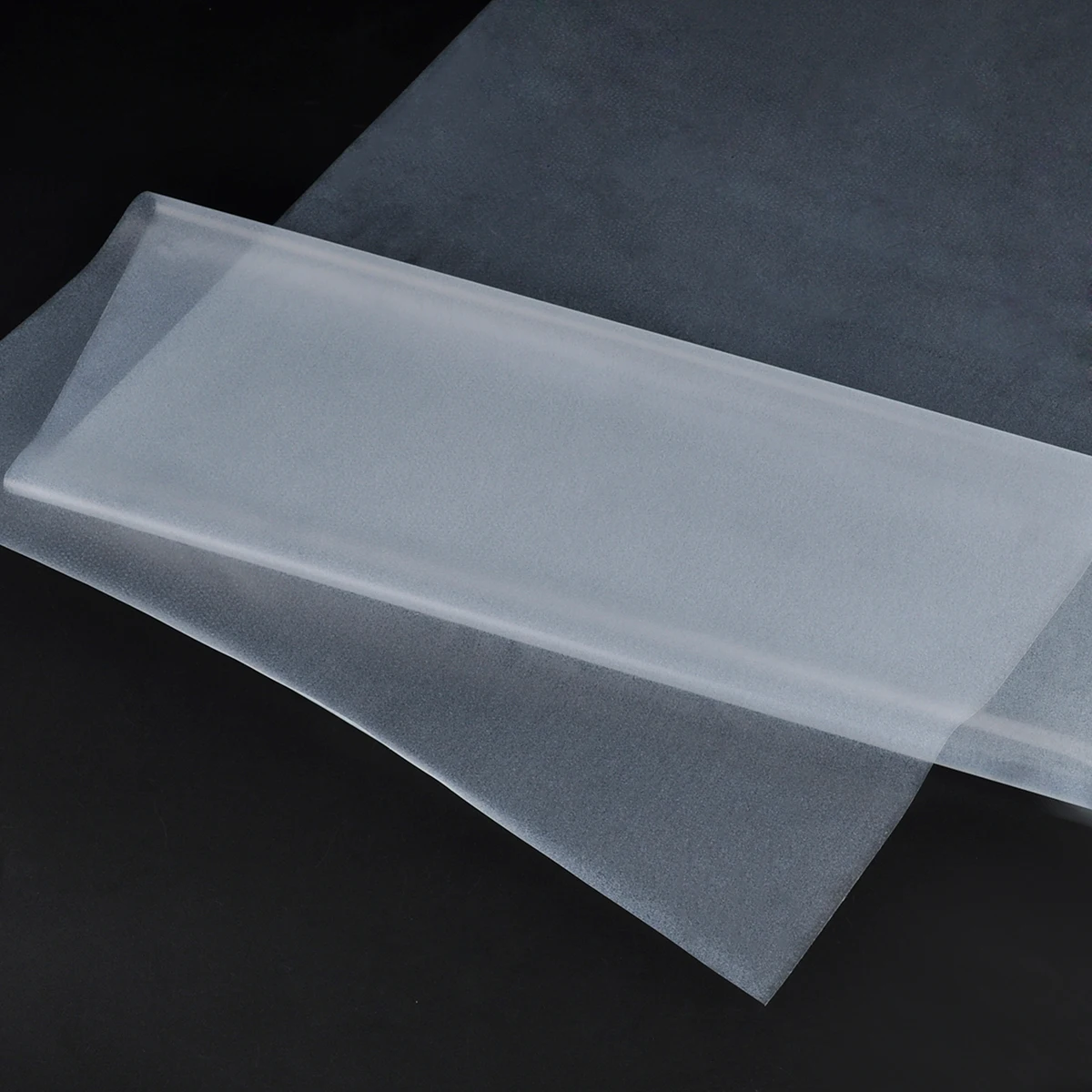

Color:

|

Transparent

|

Release Layer:

|

Glassine Release Paper

|

Thickness Range:

|

0.025mm-0.30mm

|

Width Range:

|

5mm-1580mm

|

Proportion:

|

1.18±0.02g/cm³

|

Melt Flow Index:

|

5±2g/10min(ASTM D1238-04)

|

Hardness:

|

81±3(Shore A)

|

Melting Range:

|

100-135℃ (ISO11357)

|

|

Color:

|

Transparent

|

|

Release Layer:

|

Glassine Release Paper

|

|

Thickness Range:

|

0.025mm-0.30mm

|

|

Width Range:

|

5mm-1580mm

|

|

Proportion:

|

1.18±0.02g/cm³

|

|

Melt Flow Index:

|

5±2g/10min(ASTM D1238-04)

|

|

Hardness:

|

81±3(Shore A)

|

|

Melting Range:

|

100-135℃ (ISO11357)

|

This thermoplastic film hot melt adhesive comes with a release paper backing. It can be repeatedly heated and softened for the purpose of bonding various materials. This particular type of hot melt adhesive demonstrates exceptional compatibility and performance when used with textiles, thermoplastic polyurethane (TPU), and polyvinyl chloride (PVC) substrates.

Some of the key features of this hot melt adhesive include:

1.Low melt flow index: The adhesive has a relatively low melt flow rate, which helps provide controlled and precise application.

2.Excellent hand feel and resilience: The adhesive offers a pleasant, soft-to-the-touch quality, as well as the ability to retain its shape and flexibility after application.

3.Superior heat resistance: The adhesive can withstand high temperatures without compromising its bonding strength and integrity.

4.Impressive cold resistance: This adhesive maintains its performance even in low-temperature environments, ensuring reliable bonds in a wide range of climatic conditions.

The combination of these favorable characteristics makes this thermoplastic film hot melt adhesive a versatile and effective solution for bonding a variety of materials, particularly in the textile, TPU, and PVC industries.

Colour | Transparent |

Release Layer | Glassine Release Paper |

Thickness Range | 0.025mm-0.30mm |

Width Range | 5mm-1580mm |

Proportion | 1.18±0.02g/cm³ |

Melt Flow Index | 5±2g/10min(ASTM D1238-04) |

Hardness | 81±3(Shore A) |

Melting Range | 100-135℃ (ISO11357) |

TG Temperature | -22±10℃(GB/T 19466.2-2004) |

Activation Temperature | 125-174℃(Tunsing) |

First Lamination | |

Mechanical Mold Temperature | 150℃-170℃ |

Time | 5-15 seconds |

Pressure | 0.3-0.6mpa |

Second Implanting | |

Mechanical Mold Temperature | 160℃-200℃ |

Time | 8-25 seconds |

Pressure | 0.3-0.6mpa |